Services

NDT Inspection

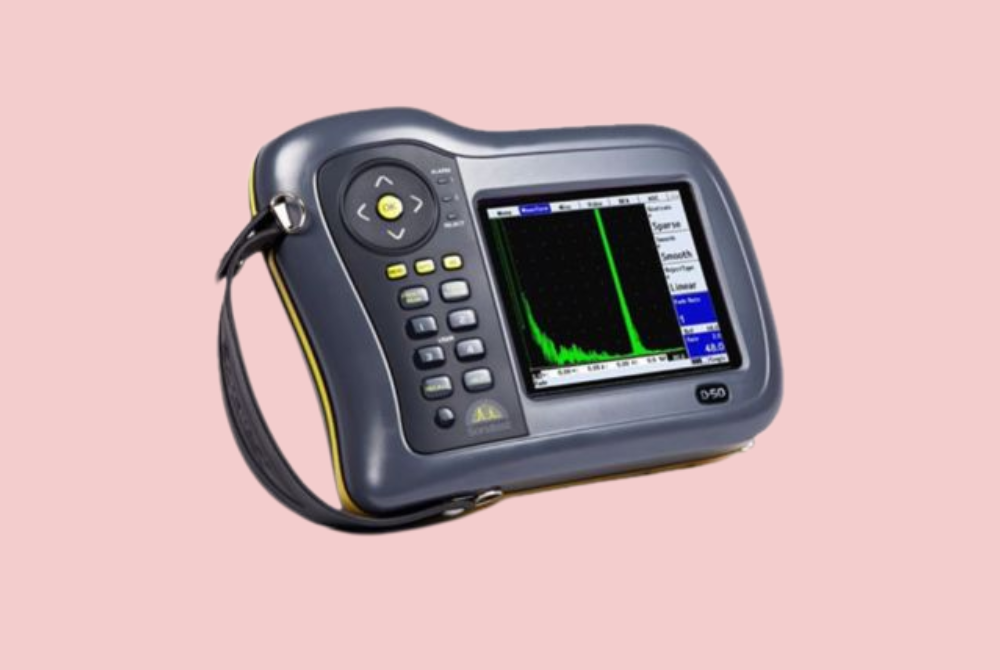

Ultrasonic Testing (UT)

Ensure accurate flaw detection and material evaluation through high-frequency sound waves, providing reliable, non-destructive testing solutions.

Dye Penetrant Test (DPT)

Reveal surface defects with accuracy using liquid penetrants, providing a reliable and non-destructive testing method for detecting cracks and flaws in various materials.

Magnetic Particle Testing (MPT)

Detect surface and near-surface defects with precision using magnetic fields and particles, ensuring reliable, non-destructive testing for ferromagnetic materials.

Hardness Test

Ensure material strength and durability with precise hardness testing, providing reliable measurements to assess resistance to deformation and wear.

X-RAY Radiatation

Radiography Testing uses X-rays or gamma rays to detect internal defects, ensuring quality and safety in industries like aerospace and construction while reducing costs.

Radiographic Film Interpretation (RTFI)

Designed for certified Level II RT personnel, this course combines industry codes, hands-on radiographs, and expert guidance to master film interpretation with confidence.

Third Party Inspections

Welding Inspection (QA/QC)

Ensures welding quality, identifies defects, and verifies compliance with industry standards for safety and reliability.

Visual Inspection (VT)

Through examination of welds for surface defects using the naked eye or magnification tools, ensuring weld quality and strict adherence to industry standards.

WQT (Welder qualification Test)

Evaluates and certifies welders' skills through practical testing. Ensures compliance with industry standards for quality and safety.

PQR (Procedure Qualification Records)

Validates welding procedures to ensure they meet project and industry standards. Confirms reliability and quality for safe and effective welds.

NDT Training, Examination & Certification

NDT Training, Examination & Certification

To ensure safety, quality, and performance, NDT professionals need proper training, examination, and certification.

Safety

General safety

Ensures welding quality, identifies defects, and verifies compliance with industry standards for safety and reliability.

Radiation Safety

Ensuring radiation safety with strict protocols and advanced NDT methods, protecting workers, the environment, and maintaining compliance with global safety standards.

NDT Trading

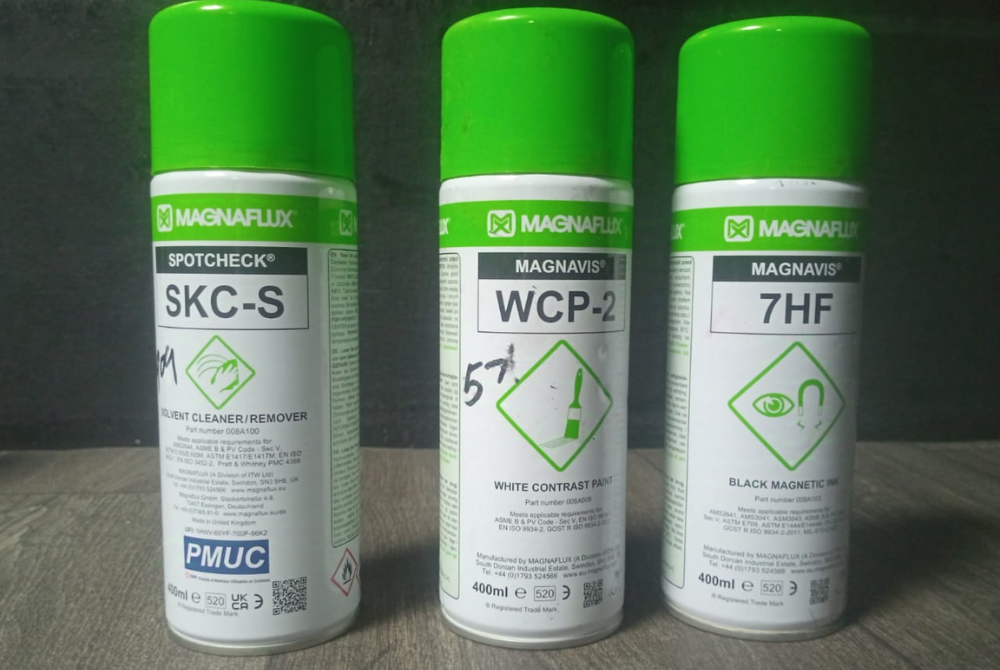

Dye Penetrant Testing (DPT)

Detects surface and near-surface flaws in ferromagnetic materials, ensuring reliability and safety.

Magnetic Particle Testing (MPT)

Identifies surface and near-surface defects in ferromagnetic materials, ensuring safety and reliability.

UT Machines

Uses ultrasonic waves to detect internal flaws, measure thickness, and ensure material integrity with precision.